Manual Filters

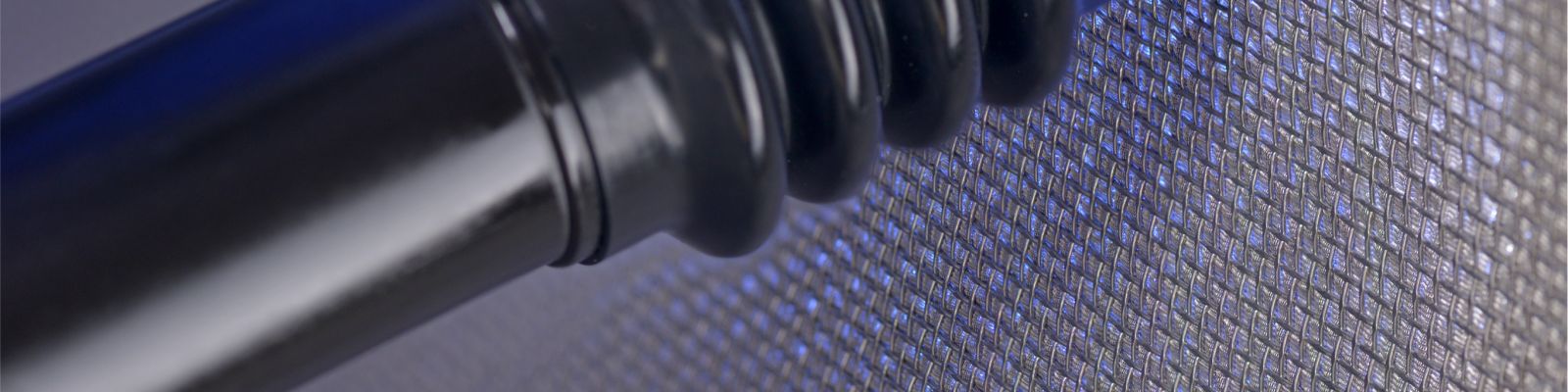

Manual Screen Filters are filters that can be cleaned completely manual or semi-automatic. The filters consist of a steel exterior and a stainless steel filter screen with PVC filter element.

The manual screen filters and semi-automatic metal screen filters are used as a safety or after filter behind the main filters. These after-filters avoid, in case of main filter defects, or after main filter operations, that the dirt can spread throughout the entire system.

Semi-automatic metal screen filters are also used as main filters in low-pollution systems or as after-filter in distribution lines. These filters are manually cleaned during operation of the system, without removing the element. Circulation filters are specially designed for water where the contamination consists of coarser contamination. The circulation filters have an internal swirl, so that the shorter sections of the screen are pressed down, leaving the screen free and open. During the flushing, a flushing valve opens at the bottom, causing the dirt to flush away immediately.

The metal screen filters are standard with 3" to 12" flange connection, both as right-angled and inline versions. The screens are available in 130, 200 and 400 microns. Ultimately a maximum flow of 60 to 650 m³/u is possible.

Circulation filters are available as inline versions between 3" and 10", screens in 130 and 200 microns. Filters have a minimum flow rate of 25 m³/u up to 500 m³/h and optional automation is possible on batteries or AC power.

The semi-automatic screen filters are available between 2" and 8" connections, with "2 and 3" available in square and from 3" to 8" as parallel versions. The screens are available in 130 and 200 microns.